Composite materials offer innovative and ground-breaking solutions to manufacturers that produce exceptional quality goods. They offer many exceptional features, such as high strength, lightweight, and other qualities designed to accomplish specific tasks.

Weighing Out the Pros and Cons

The only downside of these remarkable features is that they sometimes require technicians who possess specialized skillsets. In the case of carbon fiber, a material made up of a set of reinforced polymers, a process as simple as quality testing can be complicated and requires special machinery to accomplish correctly. This same difficulty applies when you need to find a company for cutting.

Finding a Carbon Fiber Cutting Company

Finding a carbon fiber cutting service isn’t as easy a task as is the case when you are looking for a company to alter another material, such as textiles. No matter what type of material you’re working with, you need to find quality business partners to manufacture top-quality products. In the world of composite materials, it takes a specific skill set that involves working with newer materials.

Carbon fiber cutting requires precision for a number of reasons. For example:

- You Want to Eliminate Waste

- Carbon Fiber is Expensive

- Quality Manufacturing Requires Precise Craftsmanship

A Variety of Services

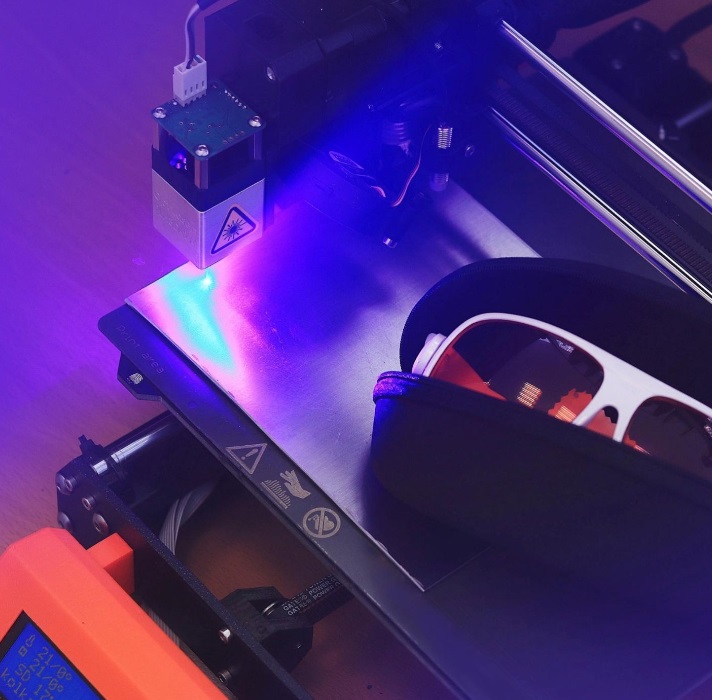

Given that there are different ways that you can cut carbon fiber composite materials, one way to determine whether the company that you’re considering hiring is able to do a professional job and meet any need you might have is to determine whether they are able to offer more than one cutting method.

Cutting by Hand

There are several options for cutting carbon fiber by hand, which include:

- Hand Saw

- Rotary Tool

- Angle Grinder

- Jig Saw

No matter what method your cutting service uses, be sure that they employ blades that are designed specifically for use on carbon fiberrather than all-purpose blades that will wear out quickly and yield a less precise result.

Safety Issues

You can learn a lot about any manufacturing or processing company by paying close attention to their safety standards. A few of the things that you’ll want to look for when assessing the safety standards of your carbon fiber cutting service will be

- Leather or Mechanic Gloves

- Safety Glasses

- Respirator or Dust Mask

- Proper Ventilation Systems

- Long Sleeves

If the company that you’re hiring for your composite materials cutting only uses the minimal standard of safety equipment or skips out on one or more essential safety protections, the chances are that they are going to put in a minimal effort when they work on your materials in general.

Getting your composite material cut by a professional company might seem like a minor part of the overall process of getting a product manufactured and into the hands of consumers, but if you aren’t careful about the quality of every stage of your manufacturing, you aren’t going to produce a consistent level of quality overall. Follow these tips when choosing a carbon fiber cutting service for your needs.