People would ask me all the time, “What is the best material to create my molds? There are a number of great materials that you should consider when you begin your design process. In this article, I am going to be talking about 3 materials: Ultem 2300, PEEK GF30 and PEEK CF30.

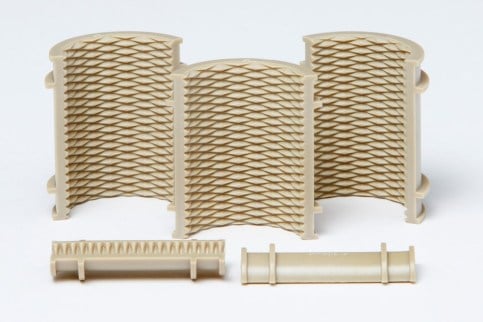

PEEK CF30, PEEK GF30, and Ultem 2300 are thermoplastic polyether ether ketones. This article will introduce three industrial plastics: PEEK CF30 plastic, PEEK GF30 plastic, and Ultem 2300. All of these are resilient to various types of chemicals, temperature resistant, and are all able to conform with your 3D-printing needs.

PEEK CF30 characteristics

PEEK CF30 is a reliable and powerful industrial-grade computer for demanding applications. With a standard height of 4U (1.75″), it fits into standard 19″ racks and weighs only 14 kg (30 lbs). It offers a multitude of interfaces, including Gigabit Ethernet and serial ports as well as a redundant power supply. The Keward PEEK CF30 rod can be ordered with more than 15 different motherboards that can be configured for the application at hand.

Covering a range of 30μm to 500μm, PEEK CF30 has been developed with specific characteristics for demanding applications such as MEMS and micro-fluidics.

The material features excellent mechanical properties, good thermal stability and maintains its mechanical properties over a broad temperature range.

This makes it particularly suitable for applications requiring a low coefficient of friction, low wear, or those exposed to harsh environmental conditions at extreme temperatures.

Additionally, PEEK CF30 is available in black and white versions to allow designers to match their parts and molds exactly with the rest of their product design.

In short, the PEEK CF30 is the perfect combination of a cool, sporty frame and high-quality lens that will give you clear vision. The PEEK frame is light and incredibly flexible, which makes it comfortable to wear for extended periods of time. It also provides a good fit for most face shapes. The PEEK CF30 has a lens that reduces reflections and gives you 100% UV protection. They are available in two attractive colors- blue and brown- to suit your taste.

PEEK GF30 and Ultem 2300

Looking for a different material? See our full line of over 150 plastics. We also stock over 50 different types of silicone including RTVs, Room Temperature Vulcanizing compounds, vacuum bagging materials, sheet gaskets, and more!

These are two of our most popular sellers. PEEK GF30 material rod is a general-purpose grade that tends to be strong, stiff, and very lightweight. Ultem 2300 is a high temperature (250° F) material that is great for functional, load-bearing parts, but it still has relatively low thermal expansion. Both materials have very high strength-to-weight ratios and are easy to machine.

Tensile strengths range from 4000 psi for GF30, to 7000 psi for Ultem 2300. Specific gravities are 1.25 g/cm³ for GF30, and 1.19 g/cm³ for Ultem 2300; both materials have excellent thermal conductivity ratings at 0.40 and 0.25 W/m · K respectively.

The Best ever Ultem 2300 rod has excellent chemical resistance to most acids, bases, alcohols, and hydrocarbons while maintaining good thermal resistance at elevated temperatures. PEEK GF30 offers similar resistance but has a higher working temperature range (up to 400° F)

The main difference between PEEK GF30 plastic and Ultem 2300 material is that the former is semi-crystalline while the latter is amorphous. Semi-crystalline materials are characterized by at least one transition from a crystalline state to an amorphous state within the same crystal structure.

Semi-crystalline materials have high-temperature resistance and can sustain higher loads than amorphous ones. They also have lower coefficients of thermal expansion than amorphous ones and have better mechanical properties than the latter.

The other big difference between these two materials lies in their flexibility properties. Very flexible material will be able to bend without exerting a large amount of force while an inflexible material would require a relatively large amount of force to bend it in half. This property is called elasticity and can be described using Young’s Modulus which indicates how.