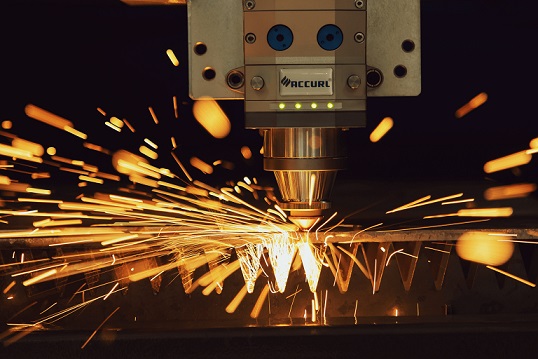

In the ever-evolving landscape of manufacturing and metal fabrication, technological advancements play a pivotal role in enhancing efficiency, precision, and overall productivity. One such groundbreaking innovation that has revolutionized the metal-cutting industry is the Fiber Laser Metal Cutting Machine.

This cutting-edge technology has rapidly gained prominence for its unparalleled speed, accuracy, and versatility, making it a preferred choice for industries ranging from automotive to aerospace.

In this comprehensive article, we will delve into the intricacies of Fiber Laser Metal Cutting Machines, exploring their working principles, advantages, applications, and the transformative impact they have on modern manufacturing processes.

Understanding Fiber Laser Technology

A. Basics of Laser Cutting

Before delving into fiber laser technology, it’s essential to grasp the fundamentals of laser cutting. Laser cutting is a non-contact process that utilizes a focused laser beam to melt or vaporize materials, resulting in precise and clean cuts.

The beam is typically generated using various laser sources, including CO2 and fiber lasers.

B. Evolution of Fiber Lasers

Fiber lasers represent a significant evolution in laser technology. Unlike traditional CO2 lasers, which rely on gas amplification, fiber lasers utilize optical fibers doped with rare-earth elements to generate the laser beam.

This design not only enhances the efficiency of the laser but also facilitates better beam quality and delivery.

Working Principles of Fiber Laser Metal Cutting Machines

A. Generation of Laser Beam

Fiber Laser Metal Cutting Machines operate by creating a high-intensity laser beam through the process of stimulated emission of radiation.

In these machines, the laser source is a diode-pumped fiber laser, where an optical pump excites rare-earth-doped fibers, resulting in the emission of a powerful laser beam.

B. Precision Focusing with Fiber Optics

Fiber optics play a crucial role in the performance of these cutting machines. The laser beam is delivered to the cutting head through flexible and high-quality optical fibers.

This enables precise focusing of the laser beam on the workpiece, ensuring accuracy and consistency in the cutting process.

C. Material Interaction

When the focused laser beam strikes the metal surface, it generates intense heat, causing the material to melt or vaporize. The high energy density of the fiber laser allows for swift and efficient material removal, resulting in precise cuts with minimal thermal distortion.

III. Advantages of Fiber Laser Metal Cutting Machines

A. Unmatched Speed and Efficiency

One of the standout features of fiber laser technology is its exceptional cutting speed.

Browse around here fiber lasers can achieve cutting speeds that far surpass traditional cutting methods, significantly reducing production time and increasing overall efficiency. This makes them particularly suitable for large-scale manufacturing operations.

B. Superior Precision and Accuracy

The high beam quality and focused delivery of fiber lasers contribute to unparalleled precision in metal cutting.

These machines can create intricate patterns and shapes with minimal kerf width, making them ideal for applications that demand precision, such as the fabrication of aerospace components and medical devices.

C. Versatility Across Material Types

Fiber Laser Metal Cutting Machines exhibit remarkable versatility when it comes to working with different materials. Whether it’s stainless steel, aluminum, copper, or exotic alloys, fiber lasers can cut through a wide range of metals with ease.

This versatility expands the scope of applications and allows manufacturers to cater to diverse industry needs.

D. Reduced Operating Costs

Compared to other laser-cutting technologies, fiber lasers are known for their energy efficiency. The diode-pumped design consumes less power, resulting in reduced operating costs for manufacturers.

Additionally, the maintenance requirements are relatively low, further contributing to cost-effectiveness over the machine’s lifespan.

Applications of Fiber Laser Metal Cutting Machines

A. Automotive Industry

The automotive sector has embraced fiber laser technology for its ability to handle various materials used in vehicle manufacturing.

From the precise cutting of sheet metal for body components to the fabrication of intricate parts, Fiber Laser Metal Cutting Machines have become indispensable in the production processes of automotive manufacturers.

B. Aerospace and Defense

In the aerospace and defense industries, where precision is paramount, fiber lasers have become the tool of choice for cutting and shaping metal components.

The ability to work with lightweight alloys and ensure tight tolerances makes fiber lasers invaluable for producing aircraft parts, missile components, and other critical elements.

C. Medical Device Manufacturing

The medical device industry demands high precision and strict quality standards. Fiber Laser Metal Cutting Machines excel in meeting these requirements, making them integral to the manufacturing of medical instruments, implants, and components used in diagnostic equipment.

D. Electronics and Consumer Goods

The electronics industry benefits from the versatility of fiber lasers in cutting and shaping metal parts for devices ranging from smartphones to household appliances.

The ability to handle thin metals with precision makes fiber lasers well-suited for the intricate components found in modern electronic devices.

Conclusion

Fiber Laser Metal Cutting Machines represent a transformative leap in the field of metal fabrication, offering unprecedented speed, precision, and versatility. From automotive giants to small-scale manufacturers, industries worldwide are embracing this cutting-edge technology to stay competitive in a rapidly evolving market.

As we look to the future, the continued evolution of fiber laser technology promises to reshape the landscape of manufacturing, bringing forth new possibilities and redefining the way we approach metal-cutting processes.

The journey from the traditional methods to the era of Fiber Laser Metal Cutting Machines marks a significant chapter in the ongoing saga of technological innovation, propelling industries towards greater efficiency and excellence.